Wear Resistant Materials

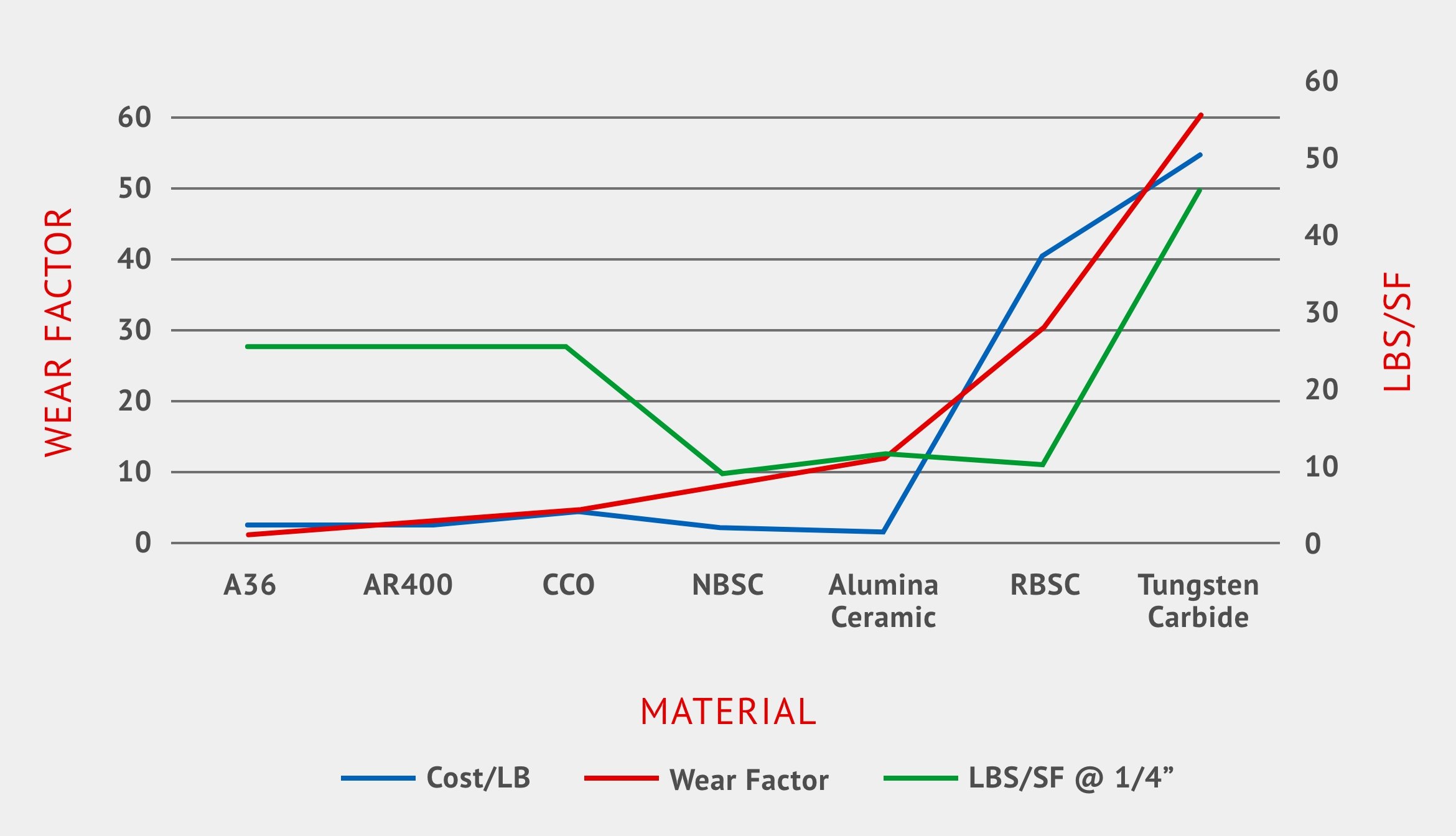

As a custom solutions provider, C.L. Smith Industrial prides itself on helping you specify the “right wear material” for your application, needs and budget. from Ceramic wear materials to tungsten carbide, our design team is experienced in evaluating many factors to guide one in selecting the ideal wear resistant materials for the intended application.

Key Wear Materials

Alumina Ceramics

Silicon Carbides

Tungsten Carbide

Chromium Carbide Overlay

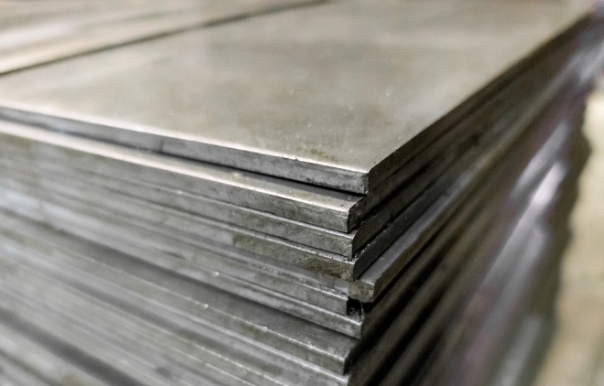

AR Plate & Pipe

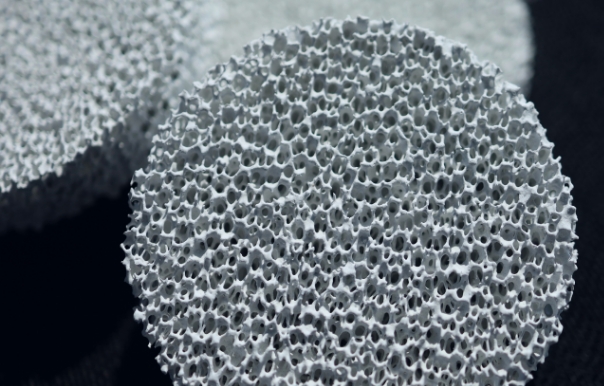

Porous Ceramic

Along with the material choices listed above we also provide components with UHMW, stainless steels, refractories, thermal sprays, wear compounds, boron carbides and direct sintered silicon carbides.

Make the "Right Choice" and contact C.L. Smith Industrial for all your wear plate and other wear product needs!

Speak With a Specialist

If you have an application to discuss, or need technical assistance, please fill out the form below.